Have any questions?

get in touchTel : +86-13641430137

Whatsapp : +86-13641430137

Skype : ourskeeper

E-mail : info@duuhnn.com

The oil level sensor is specially designed for remote real-time monitoring of fuel tank level, providing a complete solution for fleet oil level monitoring. It connects with MDVR,GPS tracker,T-Box etc via RS485/RS232 to platform.

Brand:

DUUHNNItem NO.:

DH-CS01Order(MOQ):

1pcsPayment:

TT, Paypal,Western Union,MoneyGram,AlipayPrice:

Warranty:

1YearsDelivery Time:

3-5 working days for sampleProduct Introduce

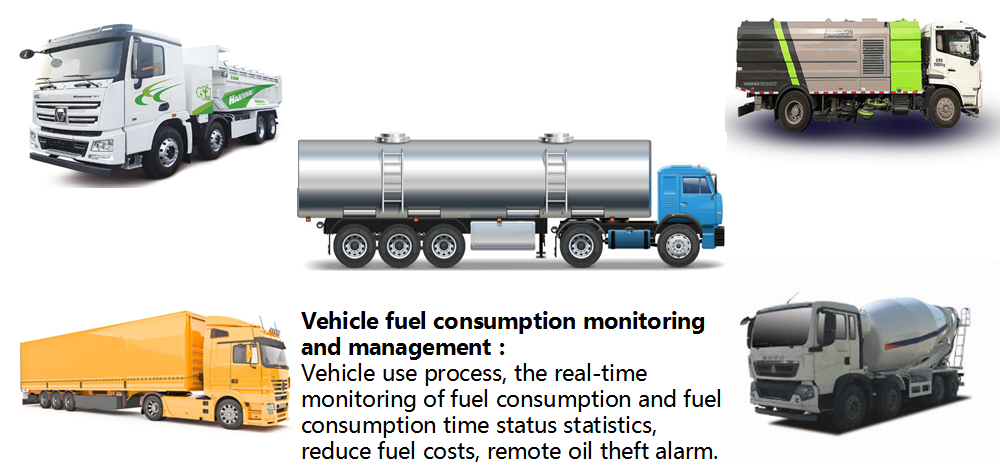

The oil level sensor is specially designed for remote real-time monitoring of fuel tank level, providing a complete solution for fleet oil level monitoring. It is widely used in trucks, farming machines, tankers, construction machinery and other fields.

The fuel level sensor is made of high specification aluminum alloy; the product is anti-corrosion and anti-corrosion, and has passed ISO14001 and CE certification. Customers can cut the length of the sensor according to the height of the fuel tank of the vehicle, and the product is highly malleable.

By matching with the vehicle communication terminal, the oil value is transmitted to the monitoring service center in real time, and the monitoring service center can digitally display the oil quantity and generate oil consumption graph and oil consumption report in real time, providing an effective technical means to solve the problems in energy management and statistics of passenger and freight enterprises, thus improving the level of enterprise management informationization and management efficiency.

The Difficulty of fuel consumption management in fleet

* Firstly, Oil theft and leakage is difficult to monitor

* Secondly, Fraudulent fueling data:

Gas stations give short measure

Drivers and gas stations collude to cheat

Fuel cards are used to refuel other cars

Unable to judge the authenticity of gasoline invoices

Data is difficult to trace

* Thirdly, Manual fuel consumption statistics:Manual ledger-based management, with data falsification and false fuel claims

Manual calculation of fuel consumption, inaccurate

Fuel consumption is not accurate to trip or specific time

Low efficiency and increased operating costs.

Work Principle

The principle of capacitive oil level sensor is to use the capacitance formed by filling the liquid medium between the positive and negative probes to change linearly with the liquid level, and convert the change of capacitance (i.e. the change of liquid level) into a standard electrical signal output. The core component of the product is a highly integrated capacitance measurement chip with precise temperature compensation and linearity correction, which has the advantages of high accuracy, high stability and continuous measurement.

Parameter

Operating Principle | Capacitive type | Operating Voltage | 5V |

Measuring method | Medium level change | Operating current | 10ma/h |

Accuracy | ±1% | Output signal | 232/485/5V |

Detection length | 0-700mm | Weight | 200g |

Measuring medium | Non-conductive liquid | Material | 70CM |

Damping factor | 1-180S | Wire length | 1M |

Calibration method | Press button | Number of wires | 4 cores |

Sensor interface wire sequence definition

RS232: This method of output sensor has 4 wires

Red 5V+ 24V supply sensor needs to be customized separately

Black GND- (RS232 ground)

Green RS232 (RXD) computer transmitter

Yellow RS232 (TXD) computer receiver

RS485: The sensor output in this way has 4 wires

Red 5V+, 24V powered sensors need to be customized separately

Black GND-(RS485 ground)

Yellow RS485 A

Green RS485 B

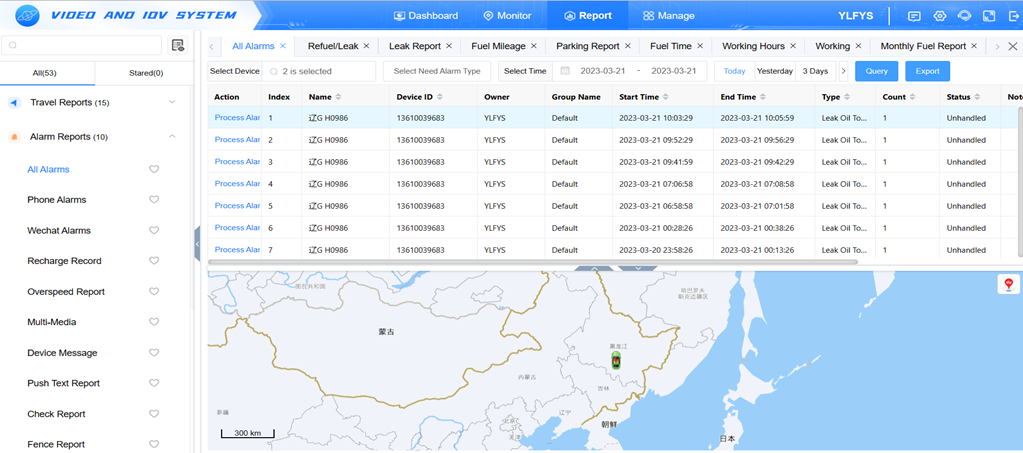

Platform Support

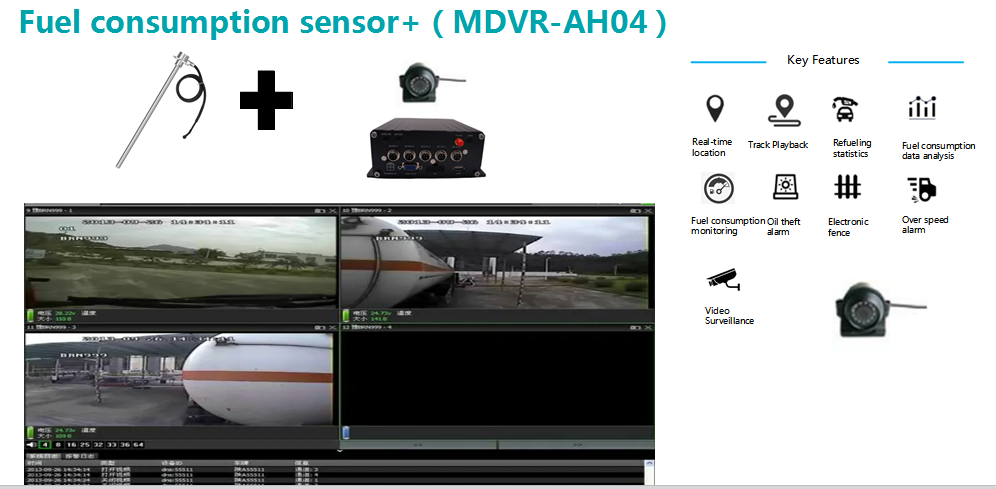

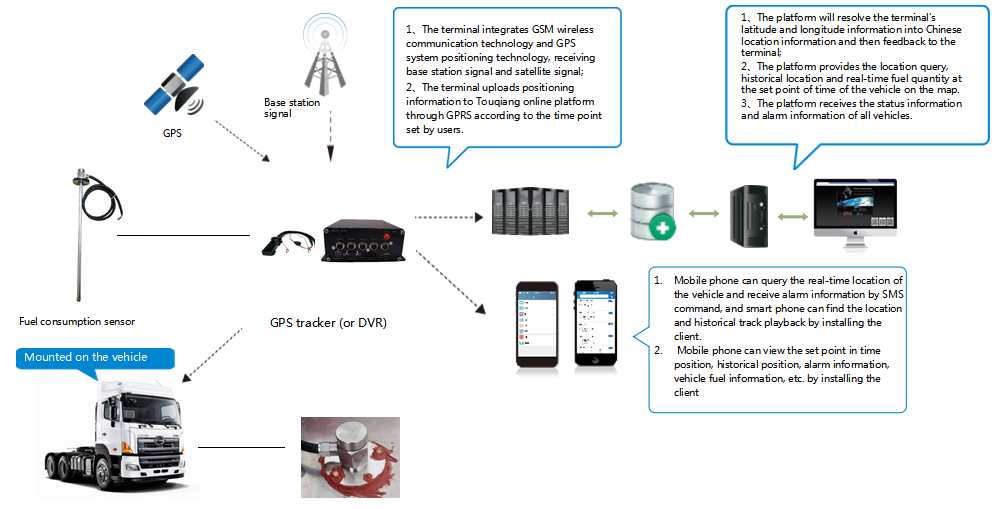

Hardware Solution

The Monitoring System Diagram

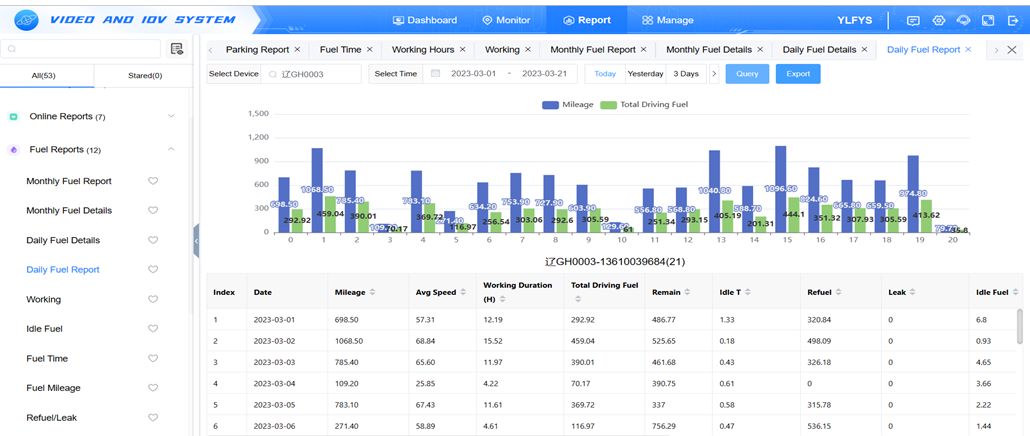

Fuel Report

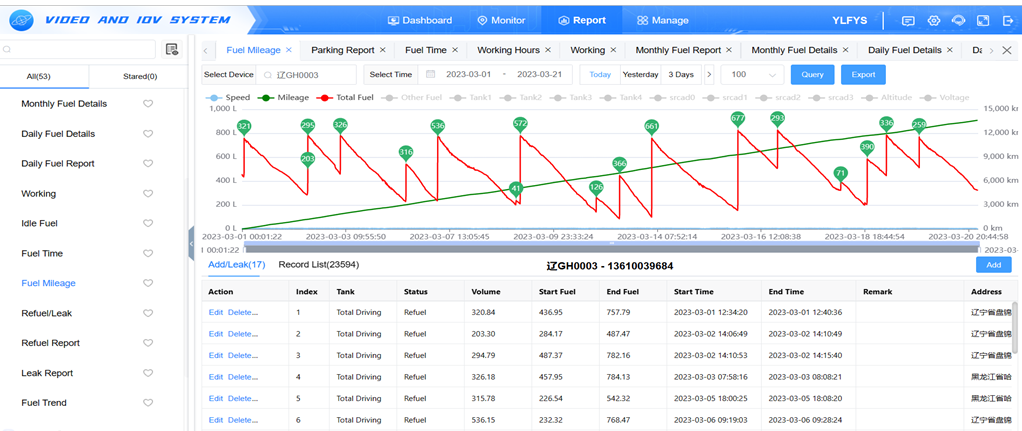

Fuel Mileage

Leak Fuel Alarm

Application

Related Tags :